Feedwater system

One of the tasks of designing a steam system is the selection of a feedwater system and its structural elements’ design. Based on many years of steam systems operation experience, and in order to ensure ease of design, ENTROPIE is ready to come up with solutions for feedwater systems selection for ENTROPIE TT200 steam boilers.

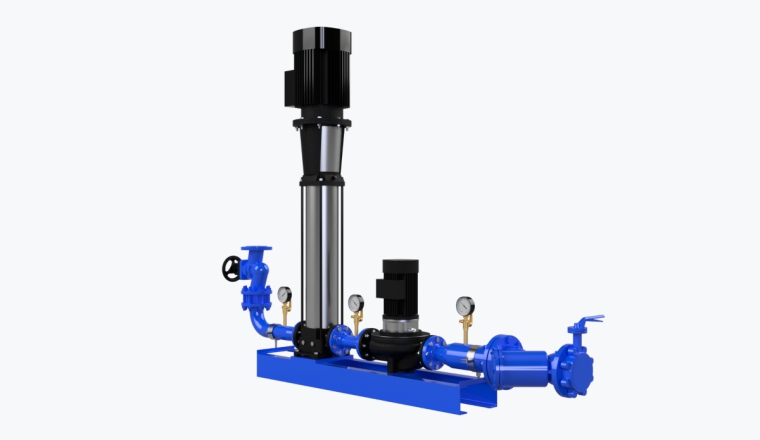

Composition of the feedwater system with the recirculation line:

- deaeration plant (ETM);

- control module with discharge line (ERM-R FW);

- feedpumps module (EPM);

- pumps control power distribution board.

The boiler is fed via a three-way feedwater control valve with a discharge line. Control is performed based on the feedback from the level transducer installed in the boiler. At closure of the feedwater supply valve, the discharge line opens to provide water circulation through the deaerator. The design provides for forced pump shutdown if the allowed recirculation time is exceeded.

Feedwater system components with frequency regulation automatics

- deaeration plant (ETM);

- control module (ERM FW);

- feedpumps module (EPM);

- power distribution switchboard for pumps frequency regulation.

The pump module with a frequency converter maintains specified pressure (usually this is the working pressure plus excess allowance) to the control valve. Frequency control is carried out according to the PID-law and is implemented with the aid of the frequency converter based on the pressure transducer feedback. Make-up valve is operated according to the PID-law in the three-position mode based on the boiler level transmitter feedback.

Similar products

Production of high-quality boilers and equipment for obtaining heat energy in the form of hot water and steam.